TEST OBJECTIVE

Determination of hardness and crispiness of banana chips using a Brookfield CTX Texture Analyzer, and Three-Point Bend (TA-TPB) Fixture.

BACKGROUND

Banana chips are usually produced from under-ripe banana slices deep-fried in oil. These chips are dry (like potato chips) and can be salted, spiced, and sugar coated. Banana chips are most often associated with having a crunchy, crispy texture. The hardness and crispiness of the banana chips will be tested using a Three-Point Bend (TA-TPB).

Chips were stored overnight at room temperature. A CTX Texture Analyzer (Figure 1) with a 10 kg load cell was used with a TA-TPB fixture (Figure 2) to perform a compression test.

This test compresses the banana chips to a set distance and measures the amount of force required to bend or break the sample.

The banana chip sample will be placed between the TA-TPB Fixture and the Fixture Base Table (TA-BT-KIT). As the blade is lowered toward the sample, it will eventually create a pressure with the bottom blades and bend the banana chip sample until it breaks. This will provide data on the hardness and crispiness of the chip sample.

METHOD

EQUIPMENT:

CTX with 10 kg Load Cell (XCTX)

Fixture Base Table (TA-BT-KIT)

Junior Three-Point Bend (TA-TPB)

Texture Pro Software (SWL-02-111)

Settings:

| Test Type: |

Compression |

| Target Type: |

Distance |

| Target Value |

3.5 mm |

| Trigger Load: |

100 g

|

| Pre-Test Speed: |

1 mm/s |

| Test Speed: |

1 mm/s |

SAMPLE PREPARATION

1. Sample was stored overnight at room temperature in original packaging.

2. Sample was removed from packaging just prior to testing.

3. Sort and select samples that are almost similar for testing.

PROCEDURE

1. Attach TA-TPB blade to the CTX Texture Analyzer.

2. Insert two table bolts into slots on analyzer base.

3. Place the Fixture Base Table on CTX and lightly screw on bolt nuts.

4. Attach TA-TPB bottom fixture to Fixture Base Table. Tighten side screws to secure fixture to table.

5. Adjust table so probe is centered on the table.

6. Once alignment is complete, secure base table by tightening the bolt nuts.

7. Slowly lower the top blade until it passes evenly through the bottom blades. This ensures proper alignment, accurate data, and test repeatability.

8. Place sample on bottom blades. Align the sample under the blade probe as centrally as possible.

9. Position probe to about 1 mm above the banana chip sample.

10. Set test parameters using the Texture Pro software.

11. Commence test.

12. Repeat steps 1-11 for all samples.

OBSERVATION

When a trigger load of 100 g is detected at the sample surface, the probe compresses the banana chip at a test speed of 1 mm/s over a specified distance of 3.5 mm. During compression the sample exerts a resistance to the force applied by the top probe. When the applied force exceeds the resistive force, the sample breaks. Once the 3.5 mm distance is met, the probe returns to the starting position.

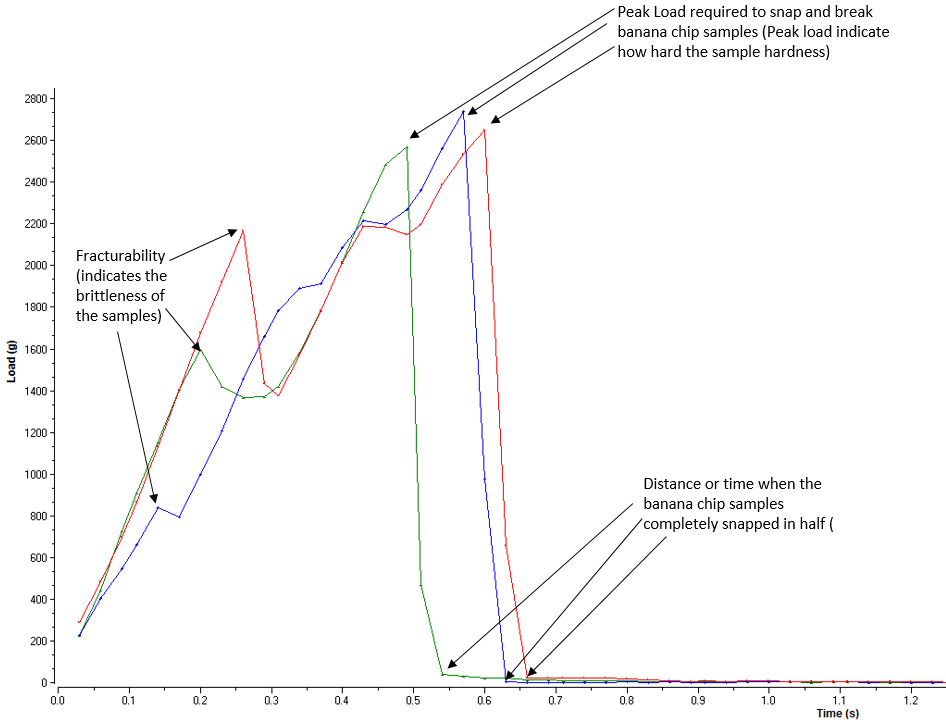

The Load vs. Time graph (Figure 6) indicates sample hardness. The Load vs. Distance graph indicates the work done to compress and bend the samples.

Banana chips were tested three times and these tests were averaged together. The graphs below report data concerning this average.

The graph above displays the positive peak loads for samples tested

The axes are Load (g) vs. Time (s).

DISCUSSION

The maximum load value is the peak load. It is a measure of sample firmness; the higher the value, the firmer the sample and the more work required to compress the sample. Hardness indicates the maximum force required to compress a food between molar teeth, while hardness work done is the necessary work to overcome the bonds within (to chew) a food.

A fracture occurs when there is a sharp decrease in load. The sensitivity can be used to specify the minimum required drop and is expressed as a percent of the hardness. If the Quantity of Fractures is calculated, all fractures will be marked on the graph. Quantity of Fractures provides a strong indication of the banana chip’s crunchiness by measuring the number of fractures during the first compression stroke (only one compression stroke was used in this test). Another key indication is fracturability, which reveals the brittleness of samples tested.

CONCLUSION

The test results can be used to determine the ideal hardness and crispiness of banana chips. All three samples tested had an average hardness value of 2,652 g force. This was the force required by the texture analyzer (with a plastic shear blade) to snap or break the banana chip on half. It is by this value that user(s) have to determine whether the banana chip is too hard or soft for the required texture. Samples also have a similar quantity of fractures, which indicate crunchiness. However, the level of brittleness, which is the fracturability value, shows vast differences between the three samples. The fracturability value is particularly useful when comparing different brands of a sample. The test can be used to facilitate consistency in production and quality control, optimize the textural attributes of a product, perform shelf-life trials, and predict the consumer’s perception of a product.

>>Download a PDF of this application note.